Projects

Farmhouse Nightstand

"This farmhouse nightstand is giving DIY a new name"

I always love sharing new projects, and even more than that I love partnering with other great builders to present those projects, and today I get to partner up with Huckleberry Ridge Furniture for the second time and I'm super excited to show you why!  A while back we partnered together on the Farmhouse X Desk and it was a hit. I mean just look at it, why wouldn't it be? I completely fell in love with this desk and now I have something else to drool over.

A while back we partnered together on the Farmhouse X Desk and it was a hit. I mean just look at it, why wouldn't it be? I completely fell in love with this desk and now I have something else to drool over. So we are back again, with a vengeance! Ok, maybe that was too much; but we are back again with another awesome 3D plan, a Farmhouse Nightstand; or side table, if you prefer, and we hope you enjoy! It's giving me Joanna Gaines Vibes.

So we are back again, with a vengeance! Ok, maybe that was too much; but we are back again with another awesome 3D plan, a Farmhouse Nightstand; or side table, if you prefer, and we hope you enjoy! It's giving me Joanna Gaines Vibes.

Be sure to go check these guys out on Instagram and Facebook to check out more of their great work after looking through these Farmhouse Nightstand plans.

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

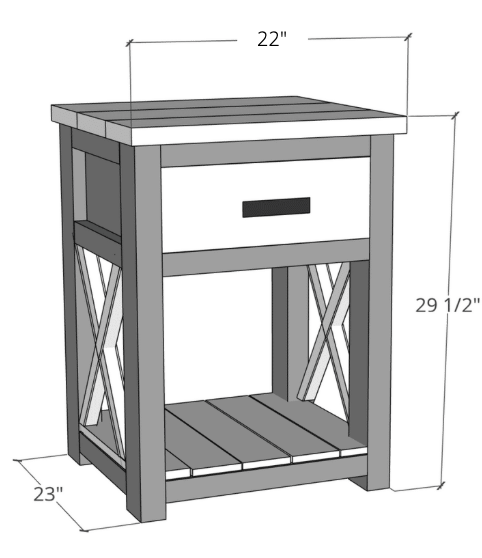

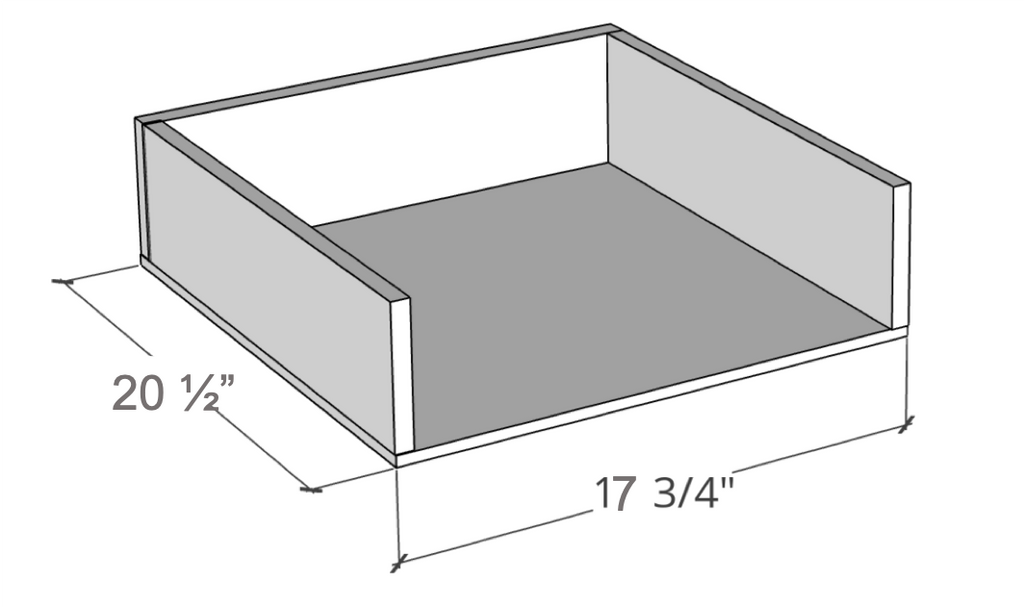

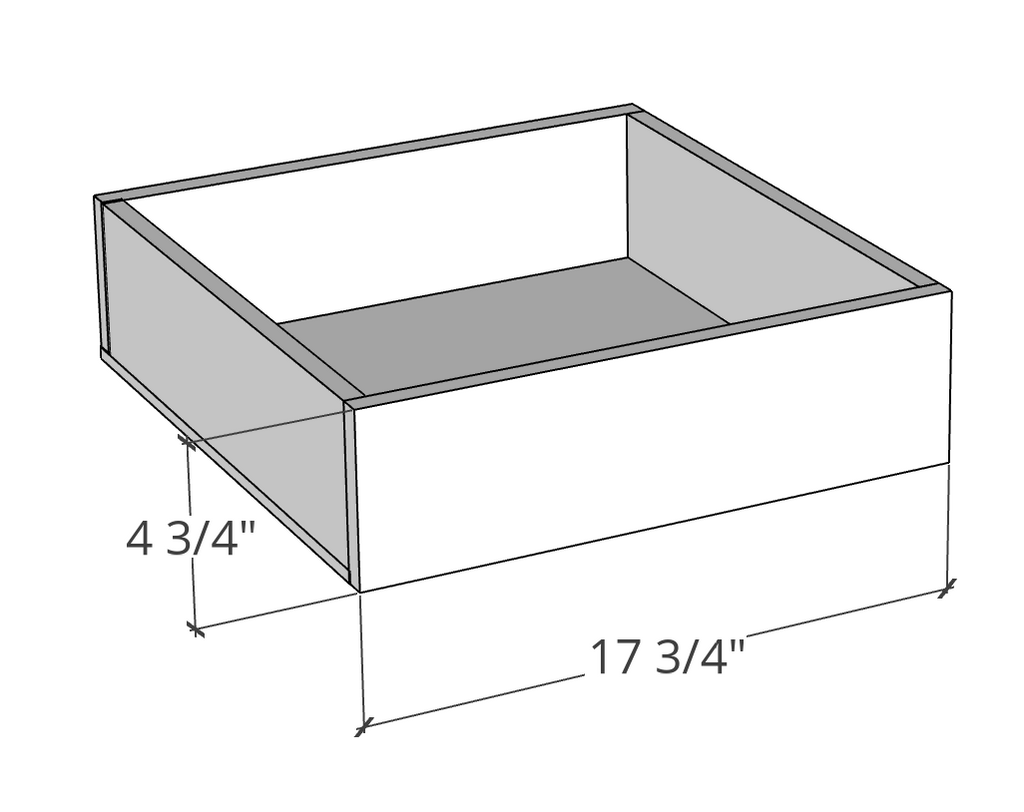

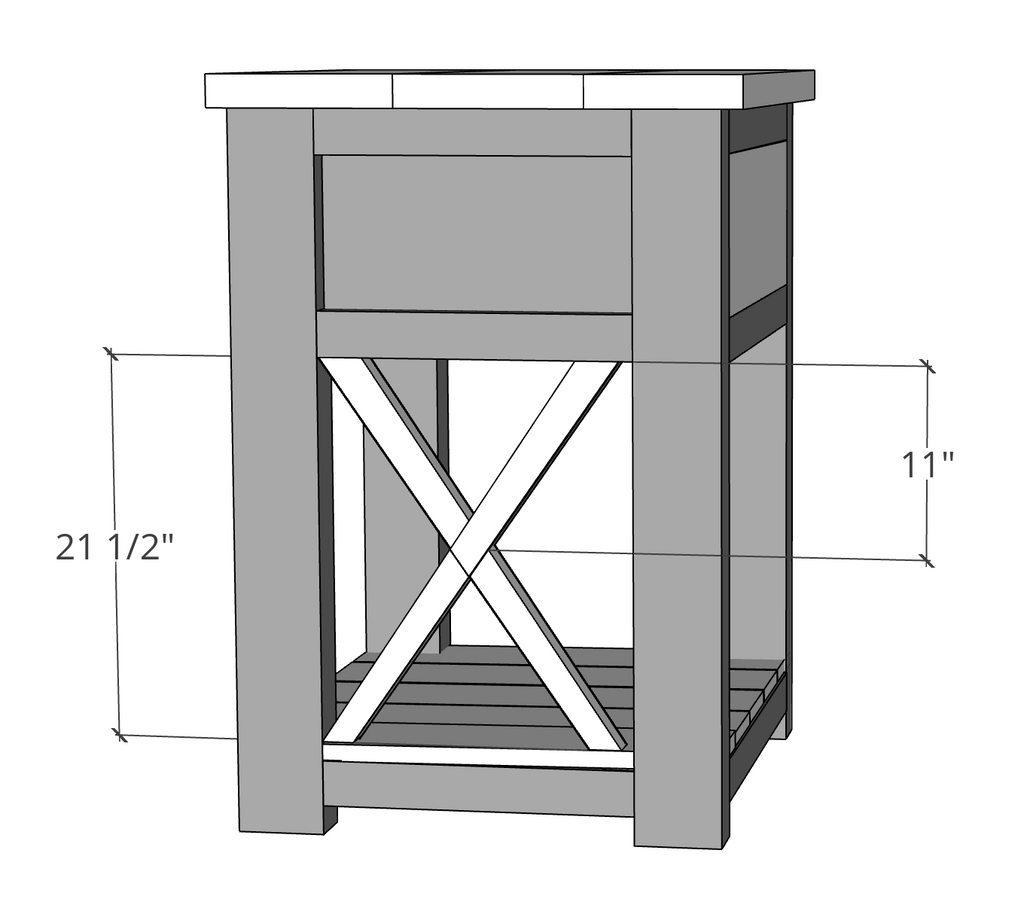

Dimensions

Materiels List

- 2 - 2 x 4 x 8 ft

- 3 - 1 x 2 x 8 ft

- 1 - 1 x 10 x 8 ft

- 2 - 2 x 6 x 8 ft

- 2 - 1 x 4 x 8 ft

- 1 - 1 x 6 x 8 ft

- 1 - 1/4" sheet of plywood - 2 x 2 ft

- 1 - 2 x 2 x 8 ft

See Printable Plans for Cut List

Now let's get to it.

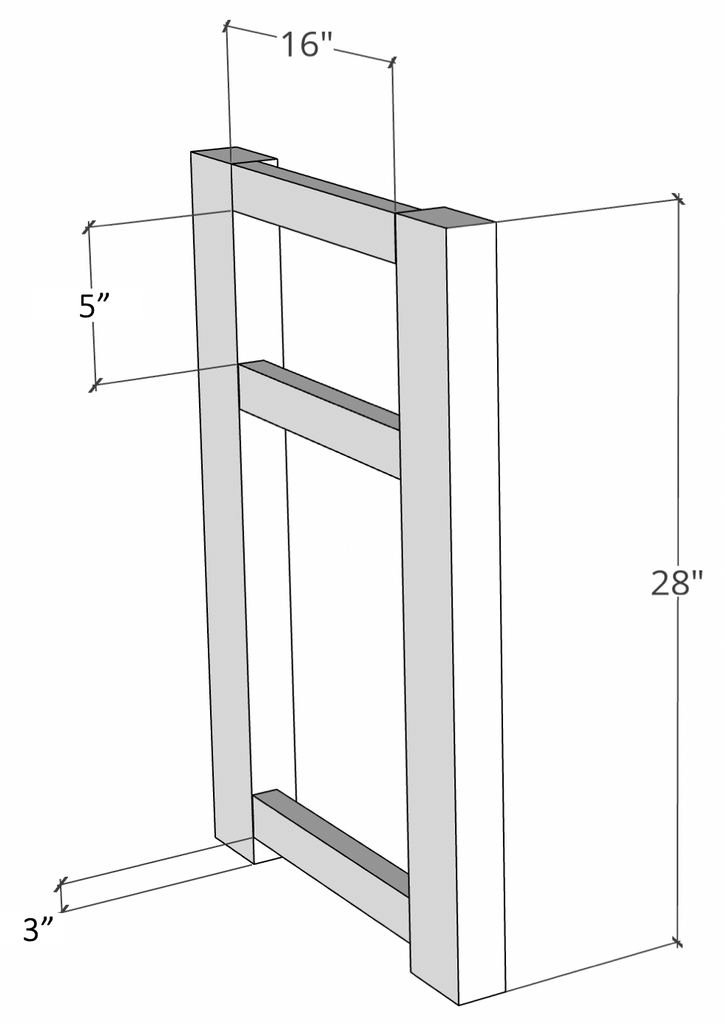

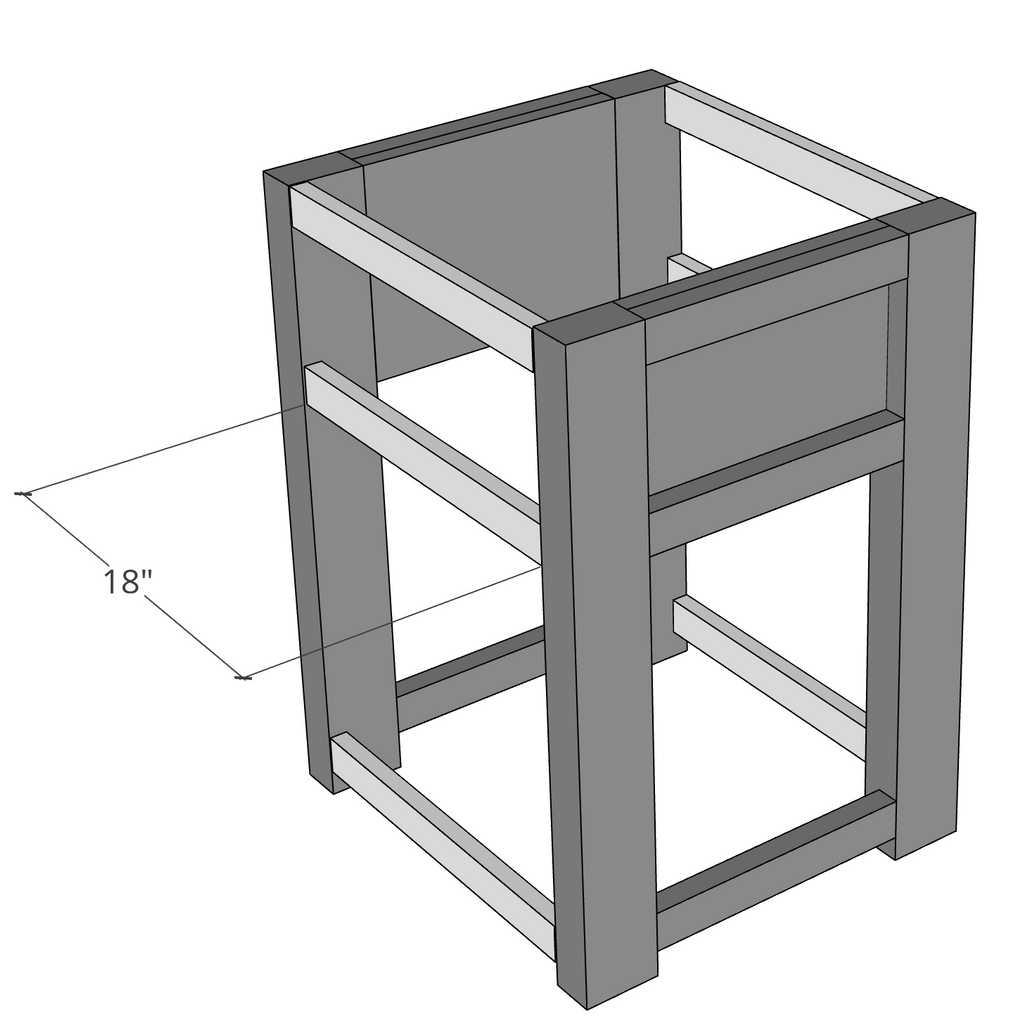

Step 1: Build Farmhouse Nightstand Sides

First you will build the farmhouse nightstand legs by attaching the legs together with the stretcher pieces using a drill and Kreg Jig K4 Pocket Hole System. You will be using 1 1/4" Pocket Hole Screws to attach the pieces together. You will be repeating this step twice so that you have two side pieces for the farmhouse nightstand.

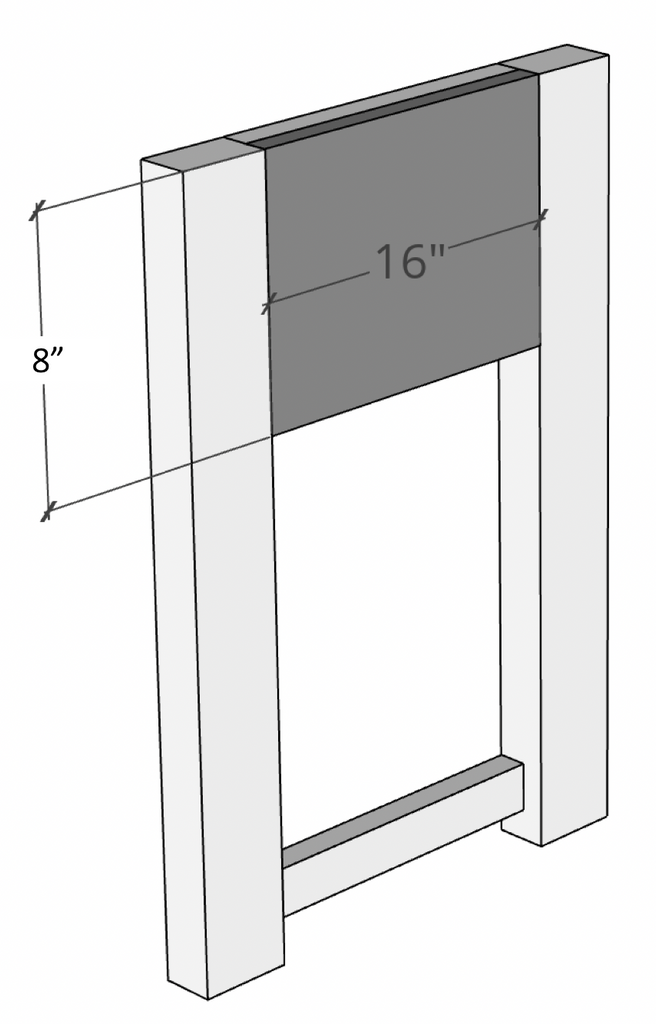

Next, you will attach the inside boards to the assembled side again using a drill and 1 1/4" Pocket Hole Screws to attach along with wood glue.

Pocket holes should be drilled on the sides of the 1x8 and drilled into the 2x4. Repeat this step for the other side of the farmhouse nightstand.

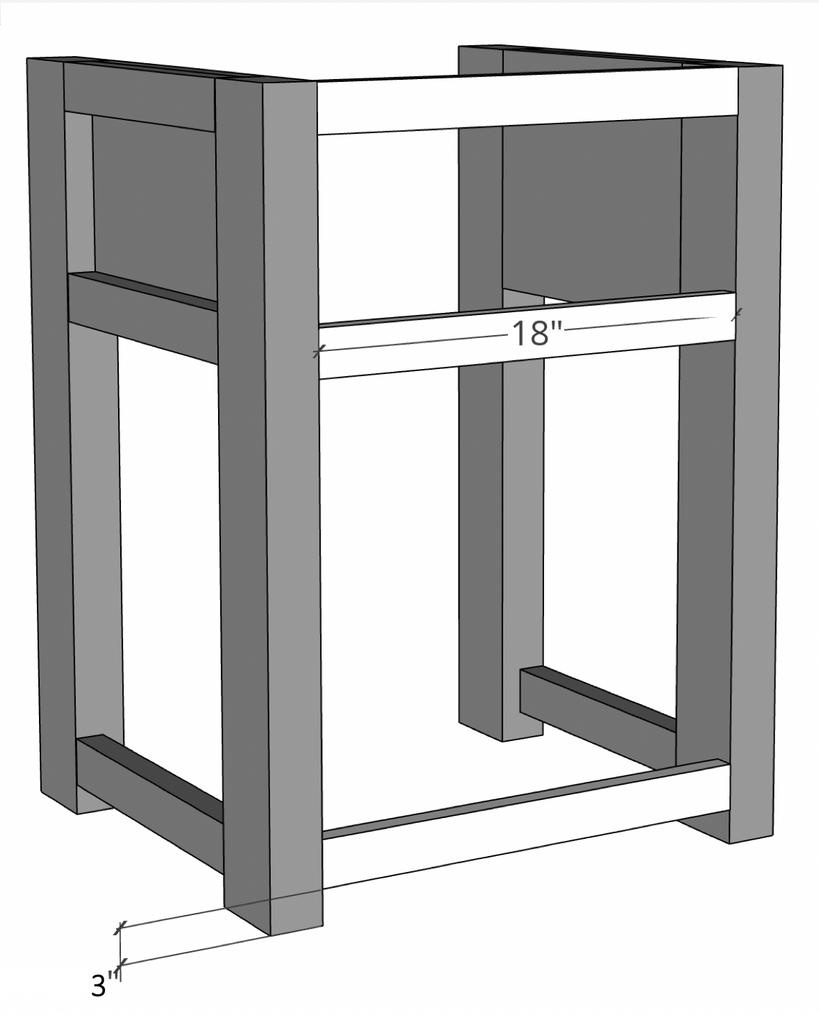

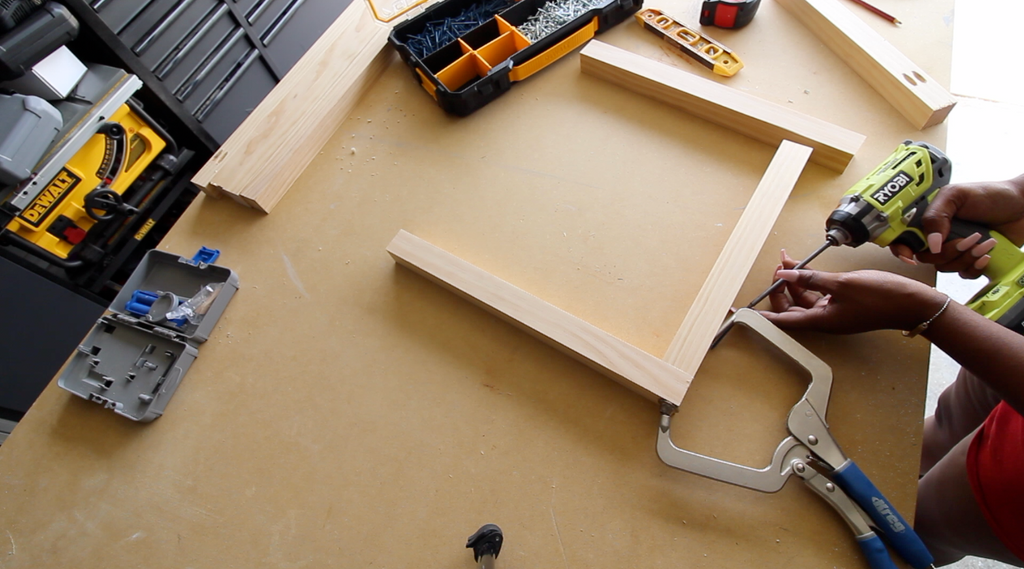

Step 2: Attach Farmhouse Nightstand Sides

Next, you will assemble the two farmhouse nightstand sides together using 1 1/4" Pocket Hole Screws to attach along with wood glue. It may be helpful to utilize a right angle clamp here to help secure the piece of wood while you are screwing in the pocket hole screws.

You will complete the assembly of the farmhouse nightstand by attaching the remainder stretcher pieces to the piece.

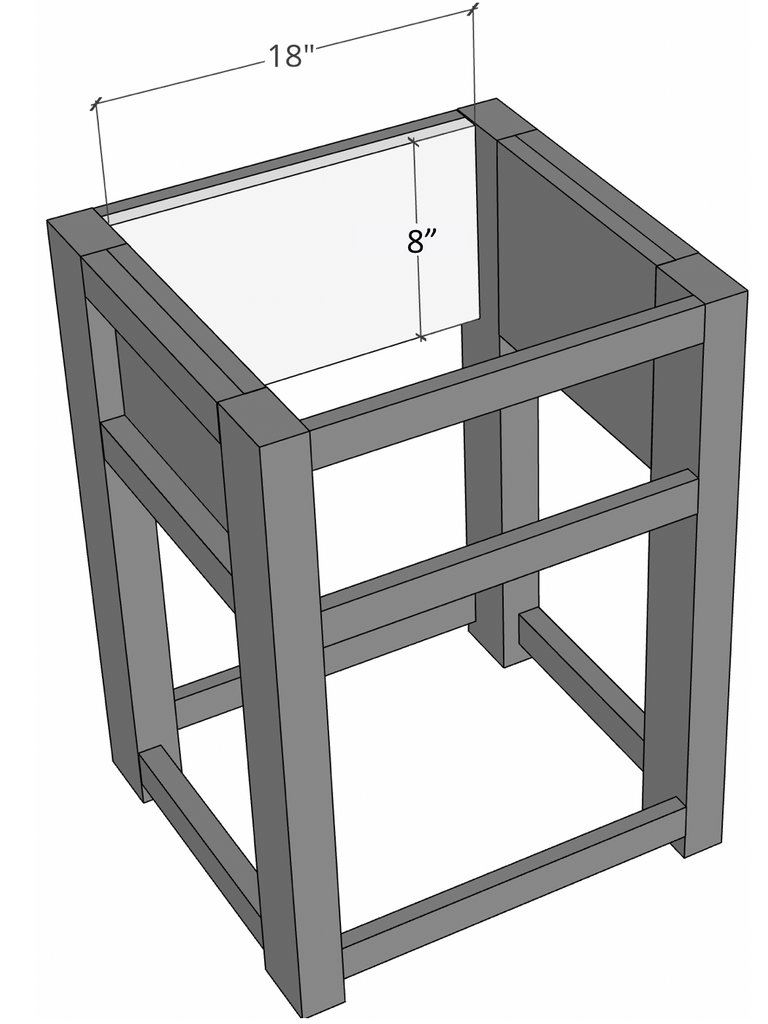

Step 3: Build the Inside of the Farmhouse Nightstand

Once the stretcher pieces are in place, you will attach the inner wood pieces of the nightstand to the assembled farmhouse nightstand again using a Kreg Jig and 1 1/4" Pocket Hole Screws.Your pocket holes should be drilled on the sides of the 1x8 and drilled into the 2x4.

Now we will start adding the pieces that will hold the nightstand drawer. We will be attaching 1x2s to the insides of the nightstand. These 1x2s should be flush with the bottom of tops inside.. Then 1x2s will be attached to the left and right side of the farmhouse nightstand using wood glue and wood screws.

These 1x2s will serve as the supports for the drawer. If you'd rather use drawer slides, feel free to skip this step and adjust drawer size as needed.

Step 4: Attach Nightstand Bottom

Next, you will add the 1x4 boards to create the bottom of the farmhouse nightstand. When dealing with the outside corners of the nightstand, you will need to use your bandsaw or a jigsaw to notch out the corners of the left and right 1x4s and leave spacing in between each board for a planked look.

Place the 1x4s out before nailing them down. Spacing should approximately be about 7/8" between each board.

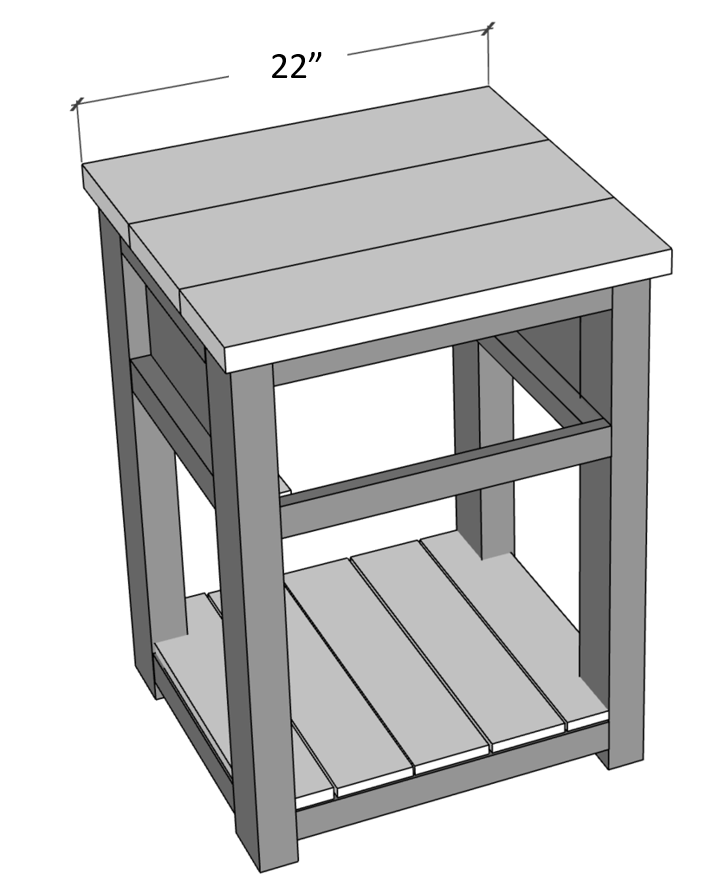

Step 5: Attach Nightstand Top

Once the nightstand base is all assembled, you will assemble the top of the farmhouse nightstand and attach it to the nightstand base using Tabletop Z clips fasteners or wood screws from the inside.

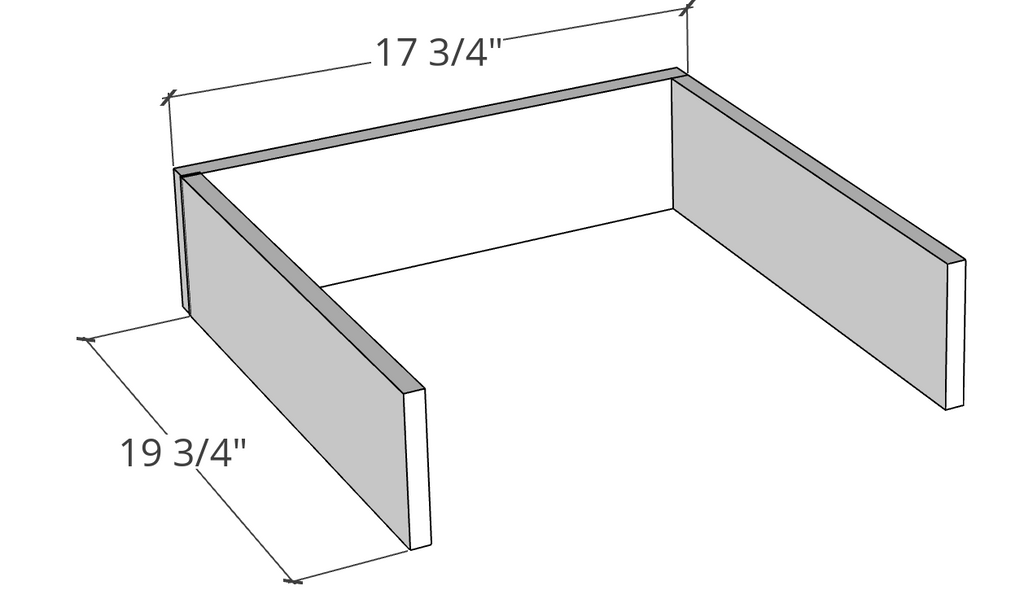

Step 6: Build Nightstand Drawers

You will begin assembling the drawers together using a Kreg Jig on a 1 1/2" setting, with 1 1/4" Pocket Hole Screws to attach along with wood glue. Utilize your right angle clamp, to clamp the boards into place while you drive in your pocket hole screws.

You will attach the 1/4" drawer bottom to the assembled drawer using a staple gun and 1" staples.

Next, you will attach the front of the drawer to the assembled box using the pre-drilled pocket holes. Once the drawer is assembled, it should slide right in on the 1x2s on the farmhouse nightstand. If you opt to use drawer slides, you will need to adjust the drawer slides accordingly.

Step 7: Add Decorative Trim

Once the drawer is built, you will begin adding the 2x2 X braces to the nightstand. It may be wise to measure the 2x2s to your already assembled nightstand first before making cuts for the best fit. The measurements should serve as just a guide.

Now this is the fun part! Finish off your nightstand with the color of your choice! Michael and Sara used Walnut Stain with matte polycrylic for the top and "Creamy" by Sherwin Williams for the bottom and don't forget a cool drawer pull for the front drawer.

The Farmhouse nightstand should now be complete! I absolutely love this project and I hope you do too. Cant wait to see all of your attempts at this build.

But I can't let you go without just one more look. Michael and Sara really knocked this out of the park. I hope you enjoyed these Farmhouse Nightstand plans, can't wait to see what you come up with.

But I can't let you go without just one more look. Michael and Sara really knocked this out of the park. I hope you enjoyed these Farmhouse Nightstand plans, can't wait to see what you come up with.

Thanks for reading guys, XOXO Ashley

DIY Leather Woven Headboard

"This DIY Leather Woven Headboard is giving me all the feels"

You can say that I've been bitten by the leather bug because I am all about these leather projects. This is my second leather project of the week and I am in love.

"This post is sponsored by The Home Depot."

I don't usually do headboards but I am so glad I decided to tackle this fun DIY because Im so satisfied with the way it came out. The best part was that this Leather Woven Headboard was only $80. Now you can't beat that.

Last week I made a DIY Leather Woven Bench and it was the inspiration for this headboard and I'm not going to lie, I have a few other projects in mind with the same kind of technique. The measurements for this headboard are for a Queen Headboard, but you can add on or take away from the wooden frame to make it whatever size you'd like. Now let's get into it.

Last week I made a DIY Leather Woven Bench and it was the inspiration for this headboard and I'm not going to lie, I have a few other projects in mind with the same kind of technique. The measurements for this headboard are for a Queen Headboard, but you can add on or take away from the wooden frame to make it whatever size you'd like. Now let's get into it.

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

Dimensions

Materiels

- 4 - 2x2s @ 6ft

Green Vinyl Fabric (4 Yards)

Ryobi 70 Piece Impact Driving Kit

Be sure to check out the how-to video before reading through the steps.

Step 1: Assemble The Bed Frame

The first step for the DIY Leather Woven Headboard was to first assemble the frame. I used four 2x2s to assemble the bed frame along with 2 1/2" pocket hole screws. To assist with the assembly, I used my Kreg Right Angle Clamp to get those pocket holes in. To make the headboard a little more sturdy, I decided to add corner braces to the four sides of the headboard.

To assist with the assembly, I used my Kreg Right Angle Clamp to get those pocket holes in. To make the headboard a little more sturdy, I decided to add corner braces to the four sides of the headboard. To help me drill in the corner braces, I used a Philip head bit from my Ryobi 70 Piece Impact Driving Kit. It includes impact rated bits with hex shank for impact drivers and drills and includes a magnetic screw guide, nut drivers and socket adaptors.

To help me drill in the corner braces, I used a Philip head bit from my Ryobi 70 Piece Impact Driving Kit. It includes impact rated bits with hex shank for impact drivers and drills and includes a magnetic screw guide, nut drivers and socket adaptors.

Step 2: Apply the Vinyl to the Headboard Frame

I first began marking the lines on my vinyl fabric by using a 2x2 and a fine point sharpie. If you want to make your leather strips bigger just make sure you mark them evenly.

I first began marking the lines on my vinyl fabric by using a 2x2 and a fine point sharpie. If you want to make your leather strips bigger just make sure you mark them evenly. Once the strips were marked, I began cutting the fabric strips using my craft scissors. Any good pair of scissors should work here. The vinyl fabric was really easy to cut through.

Once the strips were marked, I began cutting the fabric strips using my craft scissors. Any good pair of scissors should work here. The vinyl fabric was really easy to cut through.

Then I begin attaching the leather strips, one by one, to one side of the bed frame. I attached the strips using my Staple Gun and used one of the corner braces as a way to measure the spacing between the leather strips.

Then I begin attaching the leather strips, one by one, to one side of the bed frame. I attached the strips using my Staple Gun and used one of the corner braces as a way to measure the spacing between the leather strips. Once one side is secured down, pull the leather strip to the other side with a good snug and secure it down into place with your Staple Gun. It should look like this when you're done.

Once one side is secured down, pull the leather strip to the other side with a good snug and secure it down into place with your Staple Gun. It should look like this when you're done. Once one full side was secured down, I began securing down the leather strips on the top of the headboard, using my staple gun

Once one full side was secured down, I began securing down the leather strips on the top of the headboard, using my staple gun Once the top leather strips are secured down on the DIY leather headboard, you can begin weaving the leather strips through the secured strips, alternating each weave one by one. As you can see, this was the fun part because I was having way too much fun.

Once the top leather strips are secured down on the DIY leather headboard, you can begin weaving the leather strips through the secured strips, alternating each weave one by one. As you can see, this was the fun part because I was having way too much fun.

Once you attach the strips, your DIY headboard is finished! and it looks pretty darn good.

Once you attach the strips, your DIY headboard is finished! and it looks pretty darn good. I can't be any happier with how this DIY Leather Woven Headboard turned out. I am now questioning whether or not I need one for my bedroom and let's not forget that this headboard was only $80. Now that takes the cake. Let's take another look at how it came out.

I can't be any happier with how this DIY Leather Woven Headboard turned out. I am now questioning whether or not I need one for my bedroom and let's not forget that this headboard was only $80. Now that takes the cake. Let's take another look at how it came out. I am so glad I opted to go with the green, instead of the regular brown color, it gives this space so much contrast, and the green looks lovely against that natural wood.

I am so glad I opted to go with the green, instead of the regular brown color, it gives this space so much contrast, and the green looks lovely against that natural wood.

The weave pattern is just out of this world. I hope you enjoyed this project and I can't wait to see you try it out.

The weave pattern is just out of this world. I hope you enjoyed this project and I can't wait to see you try it out.

DIY Leather Woven Bench

"Who knew a DIY Leather Bench could look so trendy"

I am seeing leather benches everywhere, so they must be the hot new thing right now, so I figured I'd jump on the bandwagon and create my own DIY Leather Bench.

"This post is sponsored by the Home Depot" I wanted to take it a step further and give it a little pizzaz, so I decided to do a woven technique on the bench top, so now I have this cool DIY Leather Woven Bench and I'm so excited to finally share it with you guys.

I wanted to take it a step further and give it a little pizzaz, so I decided to do a woven technique on the bench top, so now I have this cool DIY Leather Woven Bench and I'm so excited to finally share it with you guys. The best part is, I am bringing you the full tutorial and build video today so you can recreate your own. I mean this project is just too good to keep to myself. So let's get to it!.

The best part is, I am bringing you the full tutorial and build video today so you can recreate your own. I mean this project is just too good to keep to myself. So let's get to it!.

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

Dimensions

Materiels/Tools

Bench

7 - 2x2s@ 6ft (Select Pine)

2 1/2" Pocket Hole Screws

Bench Cut List

4 - 2x2s @ 48 1/4"

12 - 2x2s @ 13 1/2"

Bench Top

1 - Project Panel (16x48)

PolyFoam ( 2x27x76)

1 Yard - Black Fabric

2 Yards - “Leather” Fabric (I used vinyl-Spot Cinnamon Whisper)

Craft Scissors

With a project like this, I know it's much easier to follow along with a video, so I made sure to catch this process on camera to help make it easier on you guys. Enjoy!

Step 1: Assemble the Base

I used my handy dandy Kreg jig to create all of the pocket holes, along with my RIDGID Drill Driver, Industry Leading with 1,300 in.-lbs. of Torque and it comes along with an Impact driver. The better part is when you by the Drill and Impact Driver Kit, you get two tools free, know who wouldn't want that?

To help assemble the base, I used my Kreg right angle clamp and Ridgid Drill and Impact Driver. The Kreg Right Angle clamp really comes in handy while building because it sort of serves as a second hand.

The Ridgid Impact Driver is the industry's leading with 2,400 in.-lbs. of torque; and it features three speeds and three specialty modes for versatility. These two tools made making this base a breeze.

The Ridgid Impact Driver is the industry's leading with 2,400 in.-lbs. of torque; and it features three speeds and three specialty modes for versatility. These two tools made making this base a breeze.

Begin assembling the base by attaching the (48 1/4") 2x2s to the (13 1/2") 2x2s using a Kreg Jig on a 1 1/2" setting, with 2 1/2" 2 1/2" pocket hole screws to attach along with wood glue. Use your Kreg Right Angle Clamp to assist.

Begin assembling the base by attaching the (48 1/4") 2x2s to the (13 1/2") 2x2s using a Kreg Jig on a 1 1/2" setting, with 2 1/2" 2 1/2" pocket hole screws to attach along with wood glue. Use your Kreg Right Angle Clamp to assist.

Attach the two middle (13 1/2") 2x2 to the assembled side using a Kreg Jig on a 1 1/2" setting, with 2 1/2" pocket hole screws to attach along with wood glue. and repeat both steps to create two bench base sides. Use your Kreg Right Angle Clamp to assist.

Attach the two assembled base sides together with the four remaining (13 1/2") 2x2s using a Kreg Jig on a 1 1/2" setting, with 2 1/2" pocket hole screws to attach along with wood glue. Use your Kreg Right Angle Clamp to assist.

The bench base should look something like this when you are complete.

If you want a cleaner look, go back through and fill all of the visible pocket holes in the back. For help on how to easily fill pocket holes, check out my technique here.

Step 2: Create the Leather Woven Bench Top

Cut the polyfill down to the size of the project panel. You should cut about a 1/2" around the project panel using craft scissors or tool of your choice. Once the polyfill is cut, take your spray adhesive and spray the foam all over one side and attach it to the wooden project panel piece.

Once the polyfill is cut, take your spray adhesive and spray the foam all over one side and attach it to the wooden project panel piece. Cut your black fabric enough to where it slightly covers the bottom of the wooden project panel piece and secure it down with your staple gun.

Cut your black fabric enough to where it slightly covers the bottom of the wooden project panel piece and secure it down with your staple gun.

Begin drawing lines on the back of your leather to create long strips. I used a 2x2 to make sure the lines were even and drew the lines with a sharpie.

Begin drawing lines on the back of your leather to create long strips. I used a 2x2 to make sure the lines were even and drew the lines with a sharpie. Once your lines are all drawn, begin cutting the strips one by one using your craft scissors

Once your lines are all drawn, begin cutting the strips one by one using your craft scissors

One by one, begin attaching each leather strap to the bench top. The straps should go directly beside each other. Do not overlap them because this may mess up the woven pattern, but get them as close as possible.

One by one, begin attaching each leather strap to the bench top. The straps should go directly beside each other. Do not overlap them because this may mess up the woven pattern, but get them as close as possible. Repeat the same exact thing for the other side so you have two sides that are secured down.

Repeat the same exact thing for the other side so you have two sides that are secured down.  Flip the bench over and begin weaving the side leather strips into the longer strips. Now this is the fun part, so have some fun with it. You will weave them all the way to the end.

Flip the bench over and begin weaving the side leather strips into the longer strips. Now this is the fun part, so have some fun with it. You will weave them all the way to the end. Once you're finished weaving, flip the bench over and start securing the loose straps down. When you're securing the straps down, you'lle want to pull on the strip a little to make sure it's nice and snug.

Once you're finished weaving, flip the bench over and start securing the loose straps down. When you're securing the straps down, you'lle want to pull on the strip a little to make sure it's nice and snug.

Once all of the straps are secured down, remove any excess straps with your craft scissors. I then sat my bench top on my base to make sure it fit, and it definitely did.

Once all of the straps are secured down, remove any excess straps with your craft scissors. I then sat my bench top on my base to make sure it fit, and it definitely did. There may be some people who are fine with their bench like this, with the natural wood, but I wanted my base to be black and WAAA-LAAAH! MY bench was complete and I am so excited with how it turned out.

There may be some people who are fine with their bench like this, with the natural wood, but I wanted my base to be black and WAAA-LAAAH! MY bench was complete and I am so excited with how it turned out.

I definitely shocked myself with this Woven Leather, I think it looks straight out of a magazine, maybe I'm biased, but it looks darn good.

I definitely shocked myself with this Woven Leather, I think it looks straight out of a magazine, maybe I'm biased, but it looks darn good. I can't way for you guys to try it out yourselves.

I can't way for you guys to try it out yourselves.

Modern Farmhouse Bookcase

“A modern bookcase that’s giving me all the farmhouse feels”

I think it’s safe to say that I love all things modern and farmhouse and today I’m excited to be partnering up with Linda for the second time to bring you the free plans for this Modern Farmhouse Bookcase Shelf.

If you've visited my blog before, you are well aware that farmhouse is definitely my friend. I have tons of plans with a farmhouse feel and this build is no different.

and can we take minute to drool over how Linda styled these shelves? She is giving me shelve envy. I hope that you enjoy this build just as much as I am because it is B-E-A-U-TIFUL!

If you didn't know, we partnered a while back on her beautiful DIY Industrial Coffee table shown below and she’s back again with this awesome Modern Farmhouse Bookcase and as you can see, she didn’t disappoint. Be sure to go check out Linda’s Instagram to see some other cool pieces she’s built.

If you didn't know, we partnered a while back on her beautiful DIY Industrial Coffee table shown below and she’s back again with this awesome Modern Farmhouse Bookcase and as you can see, she didn’t disappoint. Be sure to go check out Linda’s Instagram to see some other cool pieces she’s built.

Now let’s get to it!

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

Dimensions

Materials

5 - 2x2 @ 8ft – Select Pine

2 - 1x2 @ 8ft – Select Pine

2 - 1x3 @ 8ft – Common Board

4 – 1x10 @ 8ft – Common Board

1 - ¾” plywood – 2’x4’

Cut List

12 - 2x2 @ 9 1/4"

4 - 2x2 @ 70 1/2"

2 - 1x4 @ 51.5"

2 - 1x4 @ 12 1/4"

4 - 1x10 @ 50"

1 - ¾” plywood – 12 1/4” x 50”

Step 1 - Assemble the left side of the modern bookshelf by attaching the six (9 1/4") 2x2s to the two (70 1/2"') 2x2s using a Kreg Jig K4 Pocket Hole System on a 1 1/2" setting, with 2 1/2" pocket hole screws to attach along with wood glue. Repeat this step for the other side of the modern bookshelf.

Note: The bottom 2x2 pocket holes should be facing down, the other 2x2 pocket holes should be facing up.

Step 2 - Assemble the bottom the modern bookshelf by attaching the four 1x4 pieces to the bottom plywood piece using brad nails and wood glue. Once the bottom of the bookshelf is constructed, add in the two shelf sides by placing the shelf sides inside of the bottom box and screwing in from the bottom.

Step 3 - Add the (50") 1x10 shelves to the modern bookshelf using brad nails and wood glue. The shelves should be flush with the ends of the shelf sides.

Step 4 - Linda opted to add an additional X brain the back that really elevated this design. Feel free to measure as you go to add the 1x2 X backing. Additionally, if you want a cleaner look, go back through and fill all of the visible pocket holes. For help on how to easily fill pocket holes, check out my technique here.

and that's a wrap! Linda did such a good job with this Modern Farmhouse bookshelf and I can't wait to see your try.

DIY Hall Tree Bench

“A DIY Hall Tree Bench that’s making all the mudrooms jealous”

The entryway is usually the first thing that people see when they come into a house, so I figured why not create a fun DIY hall tree bench that could bring some style to the doorway.

“This post is sponsored by Build Something”

I know many people are always looking for fun storage ideas that aren’t just functional but stylish as well, so I have partnered up with my good friends at Kreg Tool to bring you the free plans for this beautiful DIY Hall Tree.

But before you head over, be sure to check out my process below of how I built this DIY hall tree.

I love all things modern, so I figured I would choose a design that was a little different from traditional hall tree benches that I’ve seen.

I saw this design online and just had to re-enact it. It can serve as storage, a coat rack and much more. The options are endless to what you can do with this DIY Hall Tree.

I saw this design online and just had to re-enact it. It can serve as storage, a coat rack and much more. The options are endless to what you can do with this DIY Hall Tree.

Also if you are looking for other great ideas for your entryway, be sure to check out some of my other plans posted up on the blog. All of my other entryway projects can be found here.

All of my other entryway projects can be found here.

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

Dimensions

Supplies

13 - 2x2 @ 6ft

2 - 1x12 @ 6ft

2 - Panel Boards - 17.5" x 39"

2 - 1x8 @ 6ft

1 1/2" Brad Nails

Drill

For this build, I made an attempt to try and document my process through video just in case you guys wanted to give this DIY Hall Tree a go. Check out the video above and then be sure to head over to Build Something for the free plans on how I created this DIY Hall Tree Bench.

Of course, throughout this build, I utilized my handy dandy Kreg Jig. I say this often, but my Kreg Jig is one of my top tools that I use on most, if not all, of my builds and it’s a tool I highly recommend. I personally use the K4 master system and it hasn’t disappointed me yet.

Of course, throughout this build, I utilized my handy dandy Kreg Jig. I say this often, but my Kreg Jig is one of my top tools that I use on most, if not all, of my builds and it’s a tool I highly recommend. I personally use the K4 master system and it hasn’t disappointed me yet.

If you don't use pocket holes often and you're looking for a more simpler version of the Kreg Jig, the R3 Kreg model is a great alternative and a little cheaper. Another handy tool I utilized was my Kreg clamp. I am always flying solo when it comes to building, so those clamps definitely come in handy. I would recommend this clamp if you utilize pocket holes often.

Another handy tool I utilized was my Kreg clamp. I am always flying solo when it comes to building, so those clamps definitely come in handy. I would recommend this clamp if you utilize pocket holes often.

This hall tree was fairly easy to build; I completed it in one day. Although, it may take longer for some, it was a fairly easy project to tackle and I can’t wait to see you guys tackle it yourselves.

If you're wondering where I got this cool blue workbench from; I got it from Kreg. It is one of my favorite workbenches specifically because of the fact that I can roll it around in the shop and its just the right size to be able to build my projects on top of it, so I don't always have to build from the ground. Kreg really has some great products that I've used plenty of times throughout my building journey and I always get excited when I get the chance to partner together with them. I opted to use Select Pine for this particular build because it makes it look really clean. It does drive up the price tag quite a bit, but in my opinion, it was well worth the extra money. I got it from my fav orange store, The Home Depot. Regular pine would work just fine for this build, but you may have to put in a little extra work to make it look as nice.

I opted to use Select Pine for this particular build because it makes it look really clean. It does drive up the price tag quite a bit, but in my opinion, it was well worth the extra money. I got it from my fav orange store, The Home Depot. Regular pine would work just fine for this build, but you may have to put in a little extra work to make it look as nice.

For the finish, I decided to go with one of my favorite stains, Rustoleum’s Briarsmoke. I love this stain color because it gives my build a modern, rustic look. Before applying the stain, I did wipe down the hall tree with a stain pre-conditioner first. This prevents any blotching on the build.

For the finish, I decided to go with one of my favorite stains, Rustoleum’s Briarsmoke. I love this stain color because it gives my build a modern, rustic look. Before applying the stain, I did wipe down the hall tree with a stain pre-conditioner first. This prevents any blotching on the build.

Before you head over for the free plans, let’s take one more look at this beauty. I’m really happy with how this DIY Hall Tree bench came out and I hope that you guys have fun building it as well.

Before you head over for the free plans, let’s take one more look at this beauty. I’m really happy with how this DIY Hall Tree bench came out and I hope that you guys have fun building it as well.

For the free plans, head on over to Build Something and enjoy!

But before you go, be sure to check out this other similar hall tree I built here.

See you over at Build Something!

See you over at Build Something!

Thanks for reading guys and I can't wait to see all of your great builds.

XOXO Ashley

DIY Outdoor Coffee Table

"An outdoor coffee table with a little extra underneath."

Hey everyone! I’m Cara from The Inspired Workshop , and I am excited to be teaming up with Ashley to bring you a few projects this year! First up is the tutorial and plans for this DIY modern outdoor coffee table that has an optional sandbox for the kiddos!

The build is simple and straightforward with only a few tools and materials needed. Plus the modern, sophisticated design of the coffee table easily hides the secret that it is a sandbox as well. I won’t tell anyone if you don’t! Lol! No more having to see the kids toys in the yard when you expertly disguise them into furniture!

The materials and step by step tutorial are listed below, but if you would like the downloadable plans they are available and straight to the point! You may need to use both the blog post and printable plans if there is an instruction you don’t understand!

Are you ready to get building? I bet you are!

Materials:

- 2 - 2x8x8

- 3 - 2x2x8

- 4 - 1x6x8

- 1 - 1x4x8

- 2 - 1x2x8

- Kreg Jig

- Saw

- Drill

- Stain (I used Thompson Waterseal in Teak)

NOTE: If you would just like to make the coffee table without a sandbox the supplies will be altered by only needing 2 - 1x6x8, you won’t need the 1x2x2s or the 1x4x8 or the waterproof fabric.

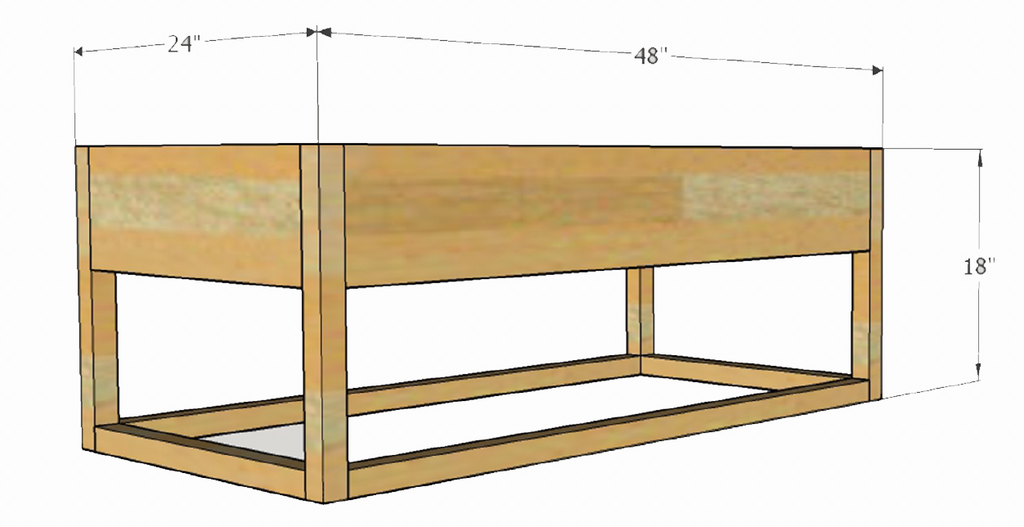

Dimensions:

Cut List:

- 2 - 2x8 @ 45” - Front and back, top rails

- 2 - 2x8 @ 21” - Side, top rails

- 4 - 2x2 @ 18” - Legs

- 2 - 2x2 @ 45” - Front and back, bottom rails

- 2 - 2x2 @ 21” Side, bottom rail

- 8 - 1x6 @ 21” - bottom of sand box (optional ¾” plywood cut at 45” x 21” - using a 2x4

project panel, if you would like a solid bottom without a liner)

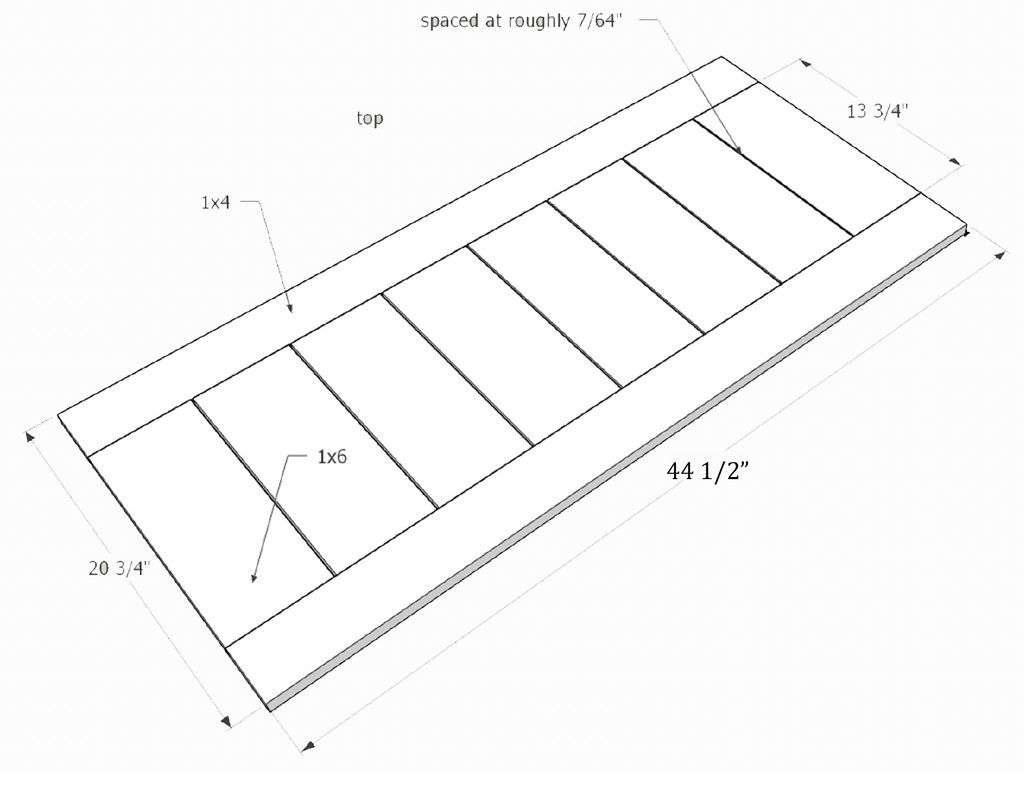

- 8 - 1x6 @ 13 ¾” - Lid Boards

- 2 - 1x4 @ 44 ½” - Lid Boards

- 2 - 1x2 @ 45” - Lid support boards

- 2 - 1x2 @19 ½” - Lid support boards

NOTE: If you want to build the coffee table without the sandbox, you can omit everything listed

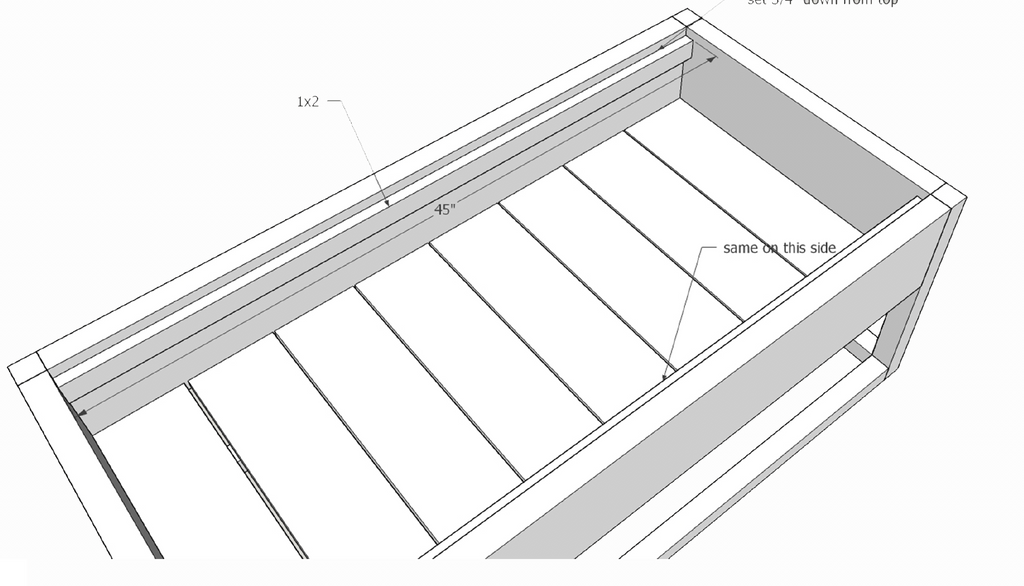

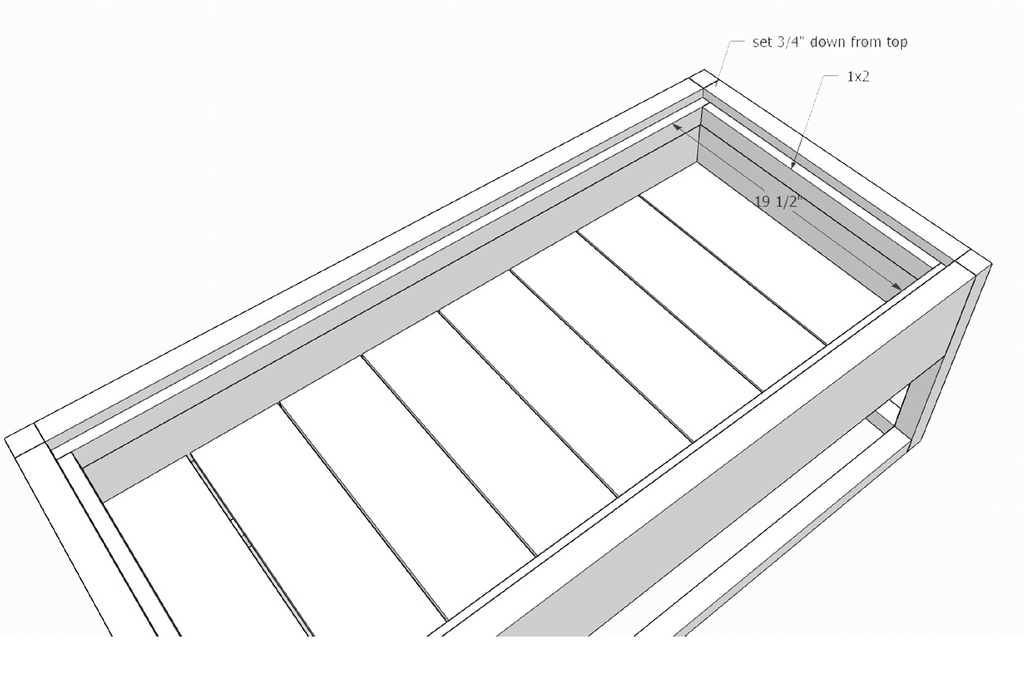

after the 8 - 1x6 @ 21”.

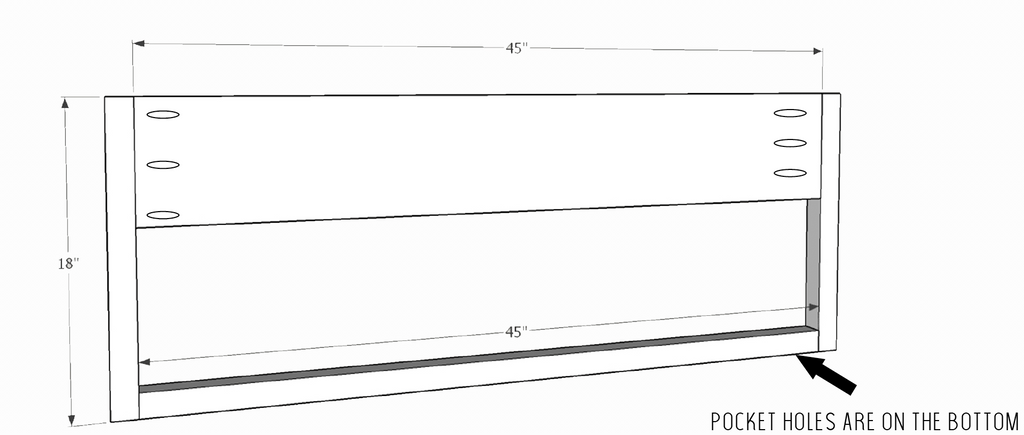

Step 1

Cut and attach the boards for the front of the sandbox. Using your Kreg Jig , drill holes at a depth of 1 ½” and use wood glue along with 2 ½” pocket hole screws to attach. Blue Kote screws are specifically made to use in outdoor projects.

The bottom 2x2 has the pocket holes placed to the bottom of the table!

Flip it over, and Viola! It looks great already!

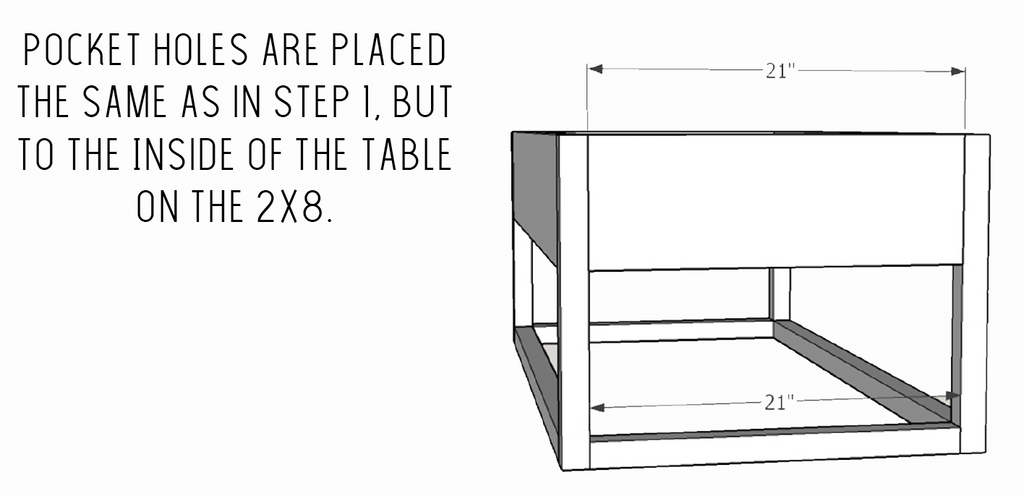

Step 2

Build another panel just like you did in Step 1, you will then have a front and back!

Step 3

Join the front of the table to the back of the table by adding the sides! You will still be using using a Kreg Jig K4 Pocket Hole System on a 1 1/2" setting, with 2 1/2" Pocket Hole Screws to attach along with wood glue. I attached the side boards (1 - 2x8 @ 21”, 1 - 2x2@21”) to each side of the top and then flipped it over and added the back.

Once it is all attached, it really starts to take shape!

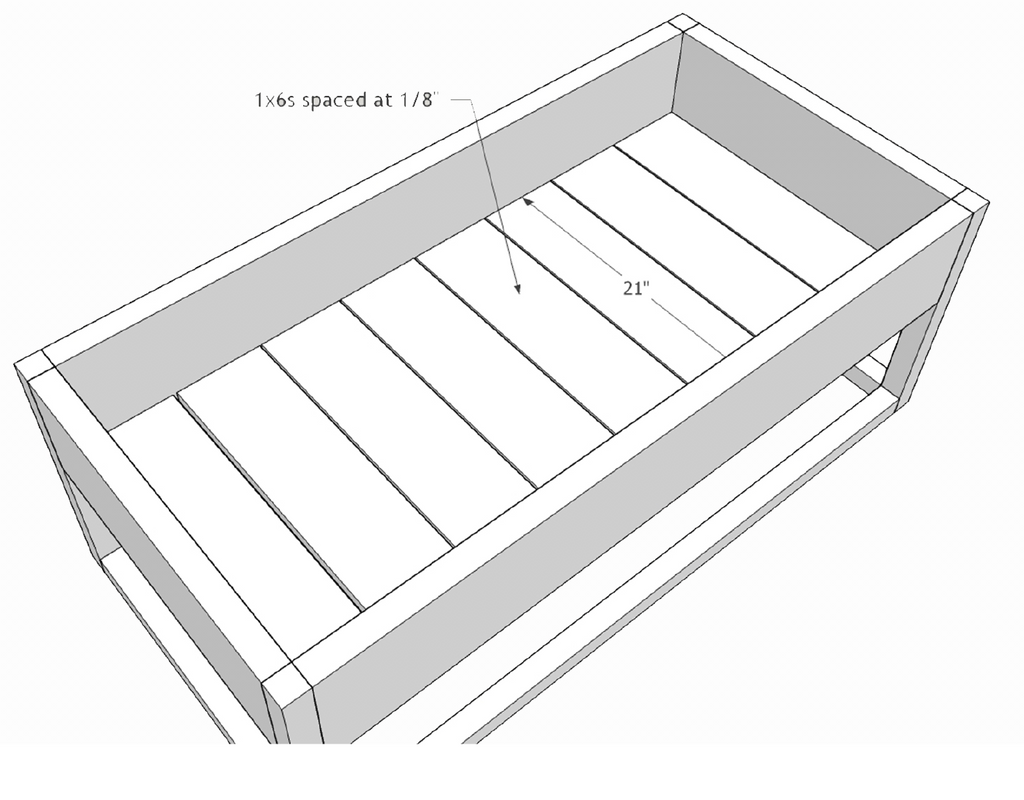

Step 4

Add the bottom 1x6 boards to create a solid surface for the liner to rest on. At first I thought it would be best to have the single boards spaced out to allow drying of the liner, but as I was building, I really came to the conclusion that it probably wouldn’t matter if you just used a solid piece of plywood, as long as it is properly sealed!

Since I used the single boards I will show you how I did it, the idea would be the same if you used a sheet of plywood. I drilled pocket holes at a depth of ¾” and used wood glue and 1 ¼” Blue Kote screws to attach.

I roughly spaced the boards ⅛” apart. I just cut a sliver of a board at about ⅛” and used that to space them all the same. The pic below shows the sandbox flipped over, which is how I attached the boards. They were a snug enough fit I didn’t have to do anything special to get them to stay in place while I screwed them in.

Don’t mind how shabby the bottom of the boards look! Lol! I was using up some not so great 1x6s I had laying around since they won’t be seen!

While the table was flipped over, I added the rubber feet here...and somehow managed to not take pictures! Ugh! But it is pretty easy, I centered the rubber foot on each 2x2 ‘leg’ and screwed it in with the screws provided. The rubber feet measure 1 ½” so they center perfectly on the leg.

NOTE: If you would like to build the coffee table without the sandbox, you can just attach those

1x6s you cut for the bottom of the sandbox and attach them as the top of the table, and boom...you’re done! Essentially it would look like this!

Step 5

At this point I sanded and stained the table so that I wouldn’t have to worry about trying the keep the stain off the liner. I then used polyurethane on the inside boards that would be beneath the liner. After comparing the poly to the Thompson Waterseal , I really could have used the Waterseal on both parts and saved myself the time of using the poly, it took forever to dry!

Step 6

I built the lid to the sandbox while all that was drying. The lid is a really simple design that allows the sand to air out to help reduce the chances of mold growing. I am not certain just yet as to how the outdoor fabric is going to hold up to the mold issue but I will try to update the post as time has passed!

You will attach all the lid boards to each other (not to the table) with the same ¾” pocket hole setting , wood glue and 1 1/4" Pocket Hole Screws. I started by attaching the two end boards first and then spaced them out from there!

The boards will be spaced at roughly a little less than ⅛” but more than 1/16”... the computer says 7/64” but that seems a little crazy for me to space, so I went with a hair over 1/16” and just have slightly larger gaps towards the center boards. For some strange reason, probably pure excitement, I didn’t get pictures of the lid before staining! Lol! So here’s the sketchup version for you!

Step 7

Attach the liner to the inside of the sandbox using a staple gun. If you used a solid piece of plywood, you don’t have to do this step! I bought 1 yard of fabric and didn’t cut it at all as I placed it inside, just stapled it and then cut it with an exacto knife .

Last step was to add the lid support boards. I just screwed them in ¾” down from the top so that the lid would fit perfectly flush with the top!

I did not glue the lid support boards, I figured if the fabric didn’t hold up well, I could easily remove the liner and replace it! I just screwed 1 ½” screws into the boards, as you can see the heads in the pictures!

You will need to seal the boards to keep the moisture from getting to them! Guess what?! Place the lid on top, and... it’s done! The kiddos are happy, momma is happy...what more could you ask for?! Lol!

Ah yes, a refreshing drink...that’s what else you could ask for! Lol!

One thing I will note… I adjusted the measurements to allow for ½” instead of a ¼” on the lid size so you can get a finger in to grab the lid and remove it, you may want to add a handle or something to make removing the lid easier. I love the sleek look and didn’t want to add a handle, but it is kinda hard if you place the lid inside the bottom like I did in the picture below! I just lifted the sandbox up slightly and then was able to remove it!

Ooh, it is so cute!

I hope you enjoyed the build! I can’t wait to come back and share another project with you all, but feel free to come visit me over at The Inspired Workshop in the meantime! See you soon!

3 Simple DIY Plant Stands

With spring in full swing, it’s the perfect time to bring fresh decor into your home. One of the most popular decor trends that's showing no sign of stopping are house plants. There are many different ways to incorporate plants in your home, some people fill their space to create a lush urban jungle while others go for a more minimalist approach. Whatever your style is there’s sure to be a plant for you.

One of the best ways to bring out your personal style is by displaying your plant on a stylish plant stand. Some of these store-bought stands can be super pricey or look mass produced. For a frugal and personalized look, consider creating your own DIY plant stand using one of these three simple tutorials. Each of the projects’ materials can be found in a hardware store and can be completed in less than a day.

DIY Tomato Cage Stand

This stand’s thin frame gives it a chic and clean look. Before purchasing a pot, make sure that you measure it’s circumference so you know it’s big enough to not fall through the smallest ring of the tomato cage you pick.

Materials needed:

- Tomato cage

- Bolt cutters

- Spray paint

- Potted plant

Step 1: Use the bolt cutters to cut the ground-end prongs off of the tomato cage. Try to make your cut as clean as possible, you may need to file down any sharp edges.

Step 1: Use the bolt cutters to cut the ground-end prongs off of the tomato cage. Try to make your cut as clean as possible, you may need to file down any sharp edges.

Step 2: Spray paint the tomato cage with the color of your choice. Metallics like rose gold or copper give the cage a more glamorous look while bright colors, like coral or aqua are great for a trendy playful look.

Step 2: Spray paint the tomato cage with the color of your choice. Metallics like rose gold or copper give the cage a more glamorous look while bright colors, like coral or aqua are great for a trendy playful look.

Step 3: Apply extra coats of paint if any metal shows through and let the tomato cage dry for about an hour. Once it’s dry place it wide side down.

Step 4: Place your potted plant in the smallest ring of the cage and enjoy your new plant stand!

Step 4: Place your potted plant in the smallest ring of the cage and enjoy your new plant stand!

DIY Wood Crate Plant Stand

This wood crate stand is very versatile and can be used as shelving for books and other storage.

Materials needed:

- Wood crates

- Paint

- Hammer

- Nails

- Plants

Step 1: Pick your paint color(s) and paint the crates. For best results, prime your crates and apply 2–3 coats depending on the opacity of the paint.

Step 1: Pick your paint color(s) and paint the crates. For best results, prime your crates and apply 2–3 coats depending on the opacity of the paint.

Step 2: Let the crates dry for a couple hours. Once they are completely dry, stack the crates and find your desired formation. Make sure to try this out in the space you plan putting the completed project to make sure it fits.

Step 2: Let the crates dry for a couple hours. Once they are completely dry, stack the crates and find your desired formation. Make sure to try this out in the space you plan putting the completed project to make sure it fits.

Step 3: After finalizing your formation, nail the crates in place. Make sure to use the right length nail to ensure that the nail doesn’t poke through to the other side.

Step 3: After finalizing your formation, nail the crates in place. Make sure to use the right length nail to ensure that the nail doesn’t poke through to the other side.

Step 4: Arrange your plants on your crate stand and enjoy!

DIY Copper Pipe Stand

The shape and finish of this DIY copper pipe stand gives off a mid-century modern look, try using a matte silver pipe finish for an industrial look. Note: some stores may cut the pipe for you when you purchase and others will ask you to buy a simple pipe cutting tool that’s very easy to use.

Materials needed:

- Pre-cut copper pipes + attachments

- 4 copper pipes at 1 inch long and ½ inch wide

- 4 copper pipes at 4 inches long and ½ inch wide

- 4 copper pipes at 5 inches long and ½ inch wide

- 4 copper pipes at 10 inches long and ½ inch wide

- 8 copper T-brackets at a ½ inch wide

- 8 copper pipe caps at a ½ inch wide

- Super glue

- Potted plant

Step 1: Assemble and glue the base, then let it dry. The copper pieces needed to assemble the base are:

Step 1: Assemble and glue the base, then let it dry. The copper pieces needed to assemble the base are:

- 4 copper pipes at 1 inch long and ½ inch wide

- 4 copper pipes at 4 inches long and ½ inch wide

- 4 copper T-brackets at a ½ inch wide

Build the inner square first, one half at a time and then to attach the extending pipes after. Start with one half of the inner square, glue the 1-inch pieces to the T-brackets, then assemble the other half and glue the two halves together. Once dry, glue the 4 inch pipes into the remaining T-bracket slots.

Step 2: Assemble and glue the legs and let them dry. The copper pieces needed to assemble the legs are:

Step 2: Assemble and glue the legs and let them dry. The copper pieces needed to assemble the legs are:

- 4 copper pipes at 5 inches long and ½ inch wide

- 4 copper pipes at 10 inches long and ½ inch wide

- 4 copper T-brackets at a ½ inch wide

Glue one 5 inch pipe and one 10 inch pipe to either end of the T-bracket, leave the perpendicular slot open. Attach the copper pipe caps to the exposed ends of the 5 inch pipe and 10 inch pipe. Repeat these steps until you have four legs.

Step 3: Attach the legs to the base with glue and let them dry. Glue an open T-brackets on the leg piece to an end of the 4 inch pipe that extends from the base. Repeat this until all of the legs are attached to the base, let the plant stand dry.

Step 3: Attach the legs to the base with glue and let them dry. Glue an open T-brackets on the leg piece to an end of the 4 inch pipe that extends from the base. Repeat this until all of the legs are attached to the base, let the plant stand dry.

Step 4: Once the glue has set (after an hour or so) add your potted plant to the stand and display your new project.

Step 4: Once the glue has set (after an hour or so) add your potted plant to the stand and display your new project.

For more details on these planters and styling tips, check out the full DIY plant stand tutorials or the infographic by ProFlowers below:

Floral Serving Tray

"Whether Easter, Spring or Summer, this DIY serving tray is sure to put all of your guest in good spirits."

With Easter around the corner, I figured I'd do a fun project to commemorate the event. But this floral serving tray applies to more seasons than just one. I am excited to share this fun DIY with you guys today.

"This post is sponsored by the Home Depot as a part of The Home Depot's Pro-Spective Campaign."

Whether you want to display food or have a fun space for displaying your drinks, this DIY floral serving tray will surely elevate any table setting. The best part is that you can continually change out the flowers for each event r season, making it a project that's always new and fresh.

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

Materiels

2 - 1x4x6 Select Pine Board

1 - 1x3x8 Select Pine Board

1 - 2x4 1/2" MDF Board

Floral Foam

Artificial Flowers

8 - White Picket Fences

White Acrylic Paint

Paint Brush

Painters Tape

Tools

Bandsaw

Luckily, I got this project all on video so be sure to check out the video tutorial after reading through the post.

Step 1: Assemble Outer Tray Box

The first thing I did was assemble the outer tray box. I used my brad nailer and 1" brad nails to assemble it together. I first started attaching the two 1x4s ( 16 7/8") to the 1/2" MDF bottom (16 7/8" x 16 7/8"). Then I added the two 1x4 outer side pieces (18 1/4) to the MDF bottom.

I used 1" brad nails to attach the pieces together. For more strength, you can also use wood glue for extra strength.

Step 2: Assemble Inner Box

Next, I started assembling the inner box. I used my Makita Impact Drill and Kreg Jigto pre-drill pocket holes into the sides of the inner box. The Makita Brushless Impact Driver features variable 2-speed and has 1,240 in.lbs of max torque in an ergonomic and compact design. The Makita Impact driver kit comes packed with a bag, charger and battery.

I drilled two pocket holes in each outer side of the 1x3s. Next I used a brad nailer to attach the four 1x3 (12 1/2") pieces together. Again, use wood glue for extra strength. Note: Make sure the pocket holes our facing outward and that the pocket holes are in the downward position.

One the inner box was assembled I started drilling the inner tray to the our tray using 1 1/4" pocket hole screws and my Makita Impact Drill

Step 3: Adding Floral Foam

Next, I cut down the floral foam on the bandsaw to fit into the sides of the food tray.

This doesn't have to fit perfectly, it just needs to be full enough to place the flowers in so it looks full. As you can see I had a few gaps between my foam.

I used a hot glue gun to hold the foam in place. You don't need a whole lot of glue fr this, just a few drops to keep the foam secure.

Step 4: Add White Picket Fences

Next step is to start adding the white picket fences. I used a hot glue gun to add the picket fences to the sides of the serving tray.

Be sure to make sure you don't put the hot glue all the way to the top of the picket fences because the top of the fence shows through on top.

Step 5: Add Flowers

Now this is the fun part. I used all types of artificial flowers to fill up the foam around the serving tray.

The flowers really made the serving tray pop, I can't get over just how good this looks. The flower arrangements really turned out better than expected.

I couldn't help but think of all the other things I could do with this project, It would also serve as a unique photo frame. Im sure my mom would love this for Mother's Day with a pic of us in the middle.

Step 6: Paint Tray Bottom

And the final step for this DIY is to paint the bottom of the serving tray white. Use painters tape to tape off the sides, and using a paint brush, paint the bottom of the tray white.

And TAA-DAH project is finished.

Serving snacks never looked so good. This fun DIY was a quick way to bring a lot of pizzazz to my table setting and the best part is that it's fitting for multiple occasions.

DIY Plate Rack

"A plate rack with a unique design."

I am super excited about sharing this build. This DIY plate rack has been on my long list of "things I need to build" for a while and I'm glad to finally mark it off the list.

"This post is sponsored by the Home Depot as a part of The Home Depot's Pro-Spective Campaign."

I am a big fan of any build that gives me some extra storage in my home and it being something stylish is and extra plus. This was a quick, fun build I was able to tackle in one afternoon and I am excited to share my process of building it.

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

The best part about this build is that I actually had the time to film it, so if my instructions get a little confusing, please feel free to check out my build video for additional help. Here it is:

Materials:

2 - 1x6 @ 6ft

1 - 1x2 @ 6ft

1 - 1x4 @ 6ft

3/8" dowel

1 1/4" Pocket Hole Screws

Danish Oil - Walnut

DAP Rapid Fuse Glue

Cut List:

2 - 1x6 @ 33"

1 - 1x6 @ 22"

3 - 1x4 @ 22"

2 - 1x2 @ 22"

Tools Used:

Step 1: First I free handed the pattern for the coat rack sides (1x6 - 33") and then used my Ryobi brushless jigsaw to cut out the patterns on both sides.

The Ryobi Brushless Jigsaw has a brushluss motor that creates more runtime, power, and faster cutting. It features a lock on trigger with a variable speed dial and is compatible with Ryobi's LITHIUM HP batteries for better performance.

To cut out the straight line on the coat rack sides I used my Diablo Ultra Finish Saw Blade. This saw blade is specifically designed to increase performance with each application. It features a thin laser cut kerf for durable and clean cuts and has carbide tips that can withstand extreme impact, allowing maximum durability.

Step 2: Next I used my Kreg jig to drill pocket holes into the support braces ( 1 x 4 - 22") for the plate rack. I used a 3/4" setting and 1 1/4" pocket hole screws.

Step 3: After the support pieces were secure I added in the (1x6 - 22") bottom shelf and attached it to the assembled plate rack using my Ryobi Brad nailer and then attached the (1x2 - 22") trim peice with brad nails to the bottom shelf.

Step 4: I then added the two additional trim pieces to the plate rack using my Ryobi Drill/Driver.

Step 5: After the coat rack was assembled I used my Bosch Spade Bits to create the holes for the 3/8" dowels and then attached the dowels using DAP Rapid Fuse Glue.

The Bosch Spade Bit set drills 10x faster than any conventional spade bit and has full thread tips that grabs the wood and pulls the bit through. Its paddle design reduces bit jamming and creates better hole entry.

once the dowels were in place she was ready for finish. I decided to try this WACO - Danish Oil for the first time and absolutely loved it. It really made the poplar pop.

Once I sanded the plate rack she was ready to be hung and man does she look good!

This fun DIY was an easy way to bring some flavor to my kitchen and I had tons f fun trying out some new tools, lets take one last look.

Thanks for reading guys. XOXO, Ashley

I acknowledge that the Home Depot is partnering with me to participate in the THD Pro-Spective Tool Review Program. As a part of the program, I am receiving compensation in the form of products and services, for the purposes of promoting The Home Depot. All expressed opinions and experiences are my own. My post complies with the Word of Mouth Marketing Association (WOMMA) Ethics Code and applicable Federal Trade Commission guidelines.

DIY Kids Teepee Bed

The coolest kids teepee bed I've ever seen!

I am excited to feature a new build today by some amazing builders. M.E Refined Designs has built this amazing kids teepee bed and I am excited to be featuring the plans for it today on the blog. If I could be a kid again, I would definitely travel back to the future and ask for a bed like this.

Before we jump into the plans, make sure to go check out more of M.E Refined Design's work on all of their social media channels. (Instagram and Facebook). This Kids Teepee bed is just one of the many cool projects they've made.

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

Dimensions

Materiels

1- 2 x 4 @ 8ft

2 - 2 x 2 @ 8ft

3 - 1 x 6 @ 8ft

11 - 1 x 4 @ 8ft

Cut List

Bed Base

- 4 - 2x4 @ 8"

- 2 - 2x2 @ 74"

- 2 - 1x6 @ 36"

- 2 - 1x6 @ 76"

- 11 - 1x4 @ 39 1/2"

Bed X Sides

- 2 - 1x4 @ 57 7/16" (50 degrees)

- 2 - 1x4 @ 72" (20 degrees)

- 1 - 1x4 @ 76"

- 2 - 1x4 @ 14 9/16" (50 degrees)

Now lets get to it!

Step 1: Attach the (76") 1x6 to the two (8") 2x4s using a Kreg Jig K4 Pocket Hole System on a 1 1/2" setting, with 2 1/2" Pocket Hole Screws to attach along with wood glue. Repeat this step for the other side of the Kids Teepee Bed.

Step 2: Attach the two teepee bed sides together by attaching the (36") 1x6 using a Kreg Jig K4 Pocket Hole System on a 1 1/2" setting, with 2 1/2" Pocket Hole Screws to attach along with wood glue Repeat this step for the other side of the Kids Teepee Bed.

Step 3: Attach the (74") 2x2 to the outer sides of the kids teepee bed using a brad nailer and brad nails or wood screws. The 2x2 should be flush with the bottom of the 1x6 stretcher. Repeat this step for the other side of the teepee bed frame.

Step 4: Attach the 11 (39 1/2") 1x4 bed stretchers to the assembled bed frame using a brad nailer and brad nails. Each stretcher should have a 3.75" spacing in between each other.

Step 5: Assemble the teepee portion of the bed by attaching the (57 7/16") 1x4 to the (72") 1x4) using a Kreg Jig K4 Pocket Hole System on a 3/4" setting, with 1 1 1/4" Pocket Hole Screws to attach along with wood glue. Then attach the (14 9/16") 1x4 to the assembled teepee frame. The outside end of the 1x4s should be cut at 20 degrees and the inside of the 1x4s should be cut at 50 degrees.

Step 6: Attach the 1x4 stretcher to the two assembled teepee frames using a Kreg Jig K4 Pocket Hole System on a 3/4" setting, with 1 1/4" Pocket Hole Screws to attach along with wood glue.

Step 7: Fill all seen pocket holes with wood for a clean look. For help on how to easily fill pocket holes, check out my technique here.

and that's that!

I really love the simplicity of this build and the natural wood finish with the black tips is absolutely perfect.

Thanks for reading guys! XOXO Ashley

Shiplap Coat Rack

"Shiplap + coat Rack = a whole lot of style"

There are some affiliate links in this post, meaning I get a small commission if you purchase through these links, at no cost to you. Click Here to read my full disclosure.

Thanks for reading guys! XOXO Ashley

I acknowledge that the Home Depot is partnering with me to participate in the THD Pro-Spective Tool Review Program. As a part of the program, I am receiving compensation in the form of products and services, for the purposes of promoting The Home Depot. All expressed opinions and experiences are my own. My post complies with the Word of Mouth Marketing Association (WOMMA) Ethics Code and applicable Federal Trade Commission guidelines.

DIY Paneled Wall

DIY Wall Paneling never looked so good!

When I first purchased my home, one thing that I always wanted to do was to paint some kind of accent wall in my living room. I have two big adjoining walls in there and I knew one of these walls would be perfect for it. So I decided to paint grey and white stripes on one of them.

After a couple of years of staring at it I realized that I needed a change, and that my 27 year old self wasn’t agreeing with my 23 year old self and feeling a little juvenile with a bland striped wall. So I decided to spruce up my walls with some DIY Paneling and man am I loving it.

After a couple of years of staring at it I realized that I needed a change, and that my 27 year old self wasn’t agreeing with my 23 year old self and feeling a little juvenile with a bland striped wall. So I decided to spruce up my walls with some DIY Paneling and man am I loving it.

Materials

- Behr Marquee - Butterscotch Amber

- 1x2x6’ (Select Pine)

- Liquid Nails

- DAP Wood Filler

- Dap Caulk

- Paint Brush

- Painters Tape

Tools Used

Step 1: Paint the Wall

I first started off by painting the wall with my Behr Marquee - Butterscotch Amber. I had to do two full coats because of the striped wall. In order to ensure clean lines, I used Painters Tape to tape off the walls before painting.

Step 2: Attach Border Trim

Before you start getting into creating the wall pattern, you want to go ahead and trim the outside of your wall project.

I opted to use this select pine instead of MDF, because the 1x2s were just the size I wanted and I didn't have to worry about cutting a MDF board down to strips.

I opted to use this select pine instead of MDF, because the 1x2s were just the size I wanted and I didn't have to worry about cutting a MDF board down to strips.

Step 3: Add Wall Paneling Pattern

I started off with the bottom corner first, and then went through line by line and added the diamonds, carefully, measuring each piece and making sure each piece was level.

To make sure the diamonds were equal, I made sure that the right and left corners were each measuring 70 degrees, using this handy angle finder. In order to make the 70 degree angle I had to make sure all of the pieces connecting the left and right sides were cut at 22.5 degrees.

To make sure the diamonds were equal, I made sure that the right and left corners were each measuring 70 degrees, using this handy angle finder. In order to make the 70 degree angle I had to make sure all of the pieces connecting the left and right sides were cut at 22.5 degrees.

It may be helpful to have a second person help make sure everything looks level. I secured the trim to the wall by applying a small amount of Liquid Nails and then shot a few 2" Brad Nails into the trim to secure it.

I attempted to layout my steps for this trim to make it easier to understand. Hopefully this helps you re-create this wall.

I attempted to layout my steps for this trim to make it easier to understand. Hopefully this helps you re-create this wall.

This wall cost me around $200 in materials and halfway through I could tell that I made the right decision. I was loving the look of the wall.

I was able to complete this project in one full day by myself, so I'm sure with some help you could definitely get this project knocked out faster.

Step 4: Fill Nail Holes and Paint

Once the trim was complete, I had to decide whether I was going to paint the trim a different color or the same color. At first, I thought about painting the trim white, but eventually decided to just paint it all the same color, and I think I made the right decision.

Honestly, I probably could have left the trim without a coat of paint, it definitely looked good without it, but I went ahead and painted it. I went through and used wood filler to fill all of the nail holes and creases. This was probably my second least favorite part, aside from the caulking.

Honestly, I probably could have left the trim without a coat of paint, it definitely looked good without it, but I went ahead and painted it. I went through and used wood filler to fill all of the nail holes and creases. This was probably my second least favorite part, aside from the caulking.

Once I filled all the nail holes with DAP Wood Filler I went through with Dap Caulk and caulked the insides of the diamonds to ensure that I would have a clean finish once I painted over the trim.

When caulking, I try not to make it too thick, otherwise you can really notice it through the paint. I tried to get the caulk lines as thin as I could possibly get them.

Now, let's take a look at the before and after!

I'm so happy with how the wall turned out, the diamonds really bring character to the room, and my friends always compliment me on this wall when they walk in and realize what's there.

I'm so happy with how the wall turned out, the diamonds really bring character to the room, and my friends always compliment me on this wall when they walk in and realize what's there.

I especially love that you can decorate the wall in many different ways and it always add character.

Whether you put a couch in front of it or a console table, this wall paneling will be the y’all of the space.

It would even serve as a great bedroom feature wall.